Install

cut linePuring ultrapure water system integrated pretreatment cartridge, reverse osmosis, post-processing cartridge in a chassis, installation takes only a few simple steps. See the following description, only a few minutes, the customer can complete the installation of equipment their own, saving factory or dealer-site installation costs. At the same time, customers to install themselves in favor of customers to better understand, use and maintenance of Puring ultrapure water system.

Before installing, please read the Manual carefully!

Operating environment requirements

- Temperature: 5~35℃.

- Humidity: Max 80%.

- No pollution, no vibration.

- Cool, dry, ventilated, non-direct sunlight.

- Drainage patency, drainage distance as short as possible.

Electricity and water rationing

- Raw water: In addition to Distillate ultrapure water system raw water for reverse osmosis pure water or distilled water, the other ultrapure water system of raw water for tap water (in line with GB5749-85 national health standards for drinking water).

- Minimum water supply pressure: 0.1MPa (Distillate can 0).

- Minimum water supply flow: 0.2m3/hr(Ultimate: 0.5m3/hr)。

- Raw water temperature: 5~35 ℃ (optimal temperature 15~25 ℃).

- Raw water pH: 4~9

- Drainage: drainage sewer or hand-washing pool.

- Mains Input: 220VAC(50Hz,10A)Three-hole socket, socket to be grounded.

The installation of Classic ultrapure water system

First of all, please check the contents of the installation parts package (see the 'packing list'), and then refer to Figure 1, in accordance with the following installation steps. (As far as possible placed pre-treatment cartridge and water storage tank under the table, the machine placed on the table.)

- Close tap water inlet valve, remove the faucet. Connected to tee joint, and hole in its side is connected to a small stainless steel ball valve, and then re-install the removed faucet (as shown in Figure 2).

- PE pipes used to connect the small stainless steel ball valve and pre-treatment cartridge (Note: pre-treatment cartridge intake ('IN' direction of the arrow) to connect the small ball valve, the outlet ('OUT' direction of the arrow) of raw water interface to connect devices.), Drainage from 2~3 minutes in order to schedule empty tube of air (Water softener should be drainage to the outlet and inlet is similar to TDS value), and then close the small stainless steel ball valve.

- PE pipes used to connect pre-treatment cartridge and ultrapure water system backside ‘raw water’ interface.

- Connect PE pipes to ‘drainage’ interface (backside of the machine), and then into the drainage sewer or hand-washing pool.

- After pure water tank ball valve is installed, PE pipes used to connect ball valve and ultrapure water system backside 'Tank' interface. then close the ball valve (as shown in Figure 3)

- Open the tap water valve, double-check whether there is any leakage in the system, if leakage, tap water valves should be closed and re-connect.

- Open the inlet small stainless steel ball valve and pure water tank ball valve.

- Power Connection: Connect the power cord to the machine 'power' interface, insert Power Socket, you can try running.

At here, Classic ultrapure water system installed, please refer to equipment manuals to get started.

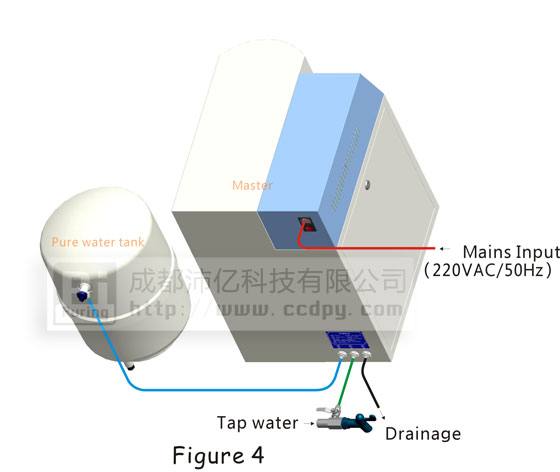

The installation of Professional ultrapure water system

First of all, please check the contents of the installation parts package (see the 'packing list'), and then refer to Figure 4, in accordance with the following installation steps. (As far as possible placed water storage tank under the table, the machine placed on the table.)

- Close tap water inlet valve, remove the faucet. Connected to tee joint, and hole in its side is connected to a small stainless steel ball valve, and then re-install the removed faucet (as shown in Figure 2).

- PE pipes used to connect the small stainless steel ball valve and ultrapure water system backside ‘raw water’ interface.

- Connect PE pipes to ‘drainage’ interface (backside of the machine), and then into the drainage sewer or hand-washing pool.

- After pure water tank ball valve is installed, PE pipes used to connect ball valve and ultrapure water system backside 'Tank' interface. then close the ball valve (as shown in Figure 3)

- Open the tap water valve, double-check whether there is any leakage in the system, if leakage, tap water valves should be closed and re-connect.

- Open the inlet small stainless steel ball valve and pure water tank ball valve.Power Connection: Connect the power cord to the machine 'power' interface, insert Power Socket, you can try running.

At here, Professional ultrapure water system installed, please refer to equipment manuals to get started.

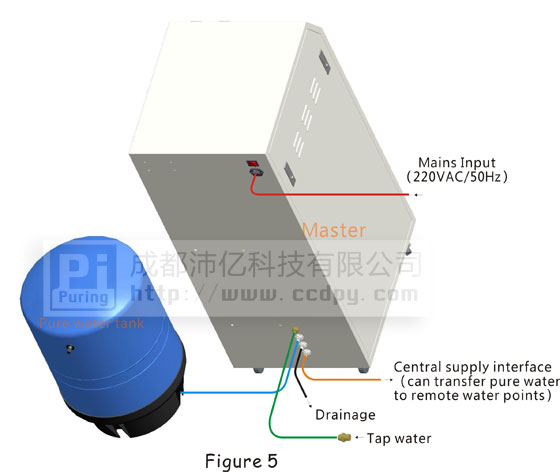

The installation of Ultimate ultrapure water system

First of all, please check the contents of the installation parts package (see the 'packing list'), and then refer to Figure 5, in accordance with the following. (Pure water tanks and machines are placed in the ground.)

- Close tap water inlet valve, wind ptfe tape to the screw thread of Quick Connector. Installation Quick Connector to the water supply interface. Maintain the water valve shut down for the following operation.

- 3/8” PE pipes used to connect the Quick Connector and ultrapure water system backside ‘raw water’ interface.

- Connect 3/8” PE pipes to ‘drainage’ interface (backside of the machine), and then into the drainage sewer.

- After pure water tank ball valve is installed, 3/8” PE pipes used to connect ball valve and ultrapure water system backside 'Tank' interface. then close the ball valve (as shown in Figure 6)

- Open the tap water valve, double-check whether there is any leakage in the system, if leakage, tap water valves should be closed and re-connect.

- Open the inlet tap water valve and pure water tank ball valve.

- Power Connection: Connect the power cord to the machine 'power' interface, insert Power Socket, you can try running.

At here, Ultimate ultrapure water system installed, please refer to equipment manuals to get started.

The installation of Distillate ultrapure water system

Distillate ultrapure water system is not configured pure water storage tank, not to discharge wastewater, equipment installation more easily and quickly.

- Pipe connection: 1/4” PE pipes used to connect the water supply interface and ultrapure water system backside ‘raw water’ interface.

- Power Connection: Connect the power cord to the machine 'power' interface, insert Power Socket, you can try running